Recent News

- Waves Group Celebrate 5 Years of Operation in Singapore

- Major Milestone Achieved in the Decommissioning of the Historic Royal Sovereign Lighthouse

- Waves Group Welcomes Captain Stanislav Ivanov as Vice President of the Houston office

- Waves Group Goes Green with Green Marine’s Project Verdant – UK’s First CTV (Crew Transfer Vessel) Powered by Hydrogen

- A New Organisational Structure for Waves Group Board of Directors

Archives

- March 2024

- December 2023

- November 2023

- June 2023

- April 2023

- February 2023

- January 2023

- November 2022

- October 2022

- September 2022

- August 2022

- July 2022

- June 2022

- May 2022

- April 2022

- March 2022

- February 2022

- September 2021

- June 2021

- May 2021

- March 2021

- February 2021

- January 2021

- December 2020

- October 2020

- September 2020

- August 2020

- July 2020

- April 2020

- March 2020

- February 2020

- January 2020

- December 2019

- November 2019

- October 2019

- September 2019

- August 2019

- June 2019

- May 2019

- April 2019

- March 2019

- February 2019

- January 2019

- November 2018

- October 2018

- September 2018

- July 2018

- May 2018

- September 2017

- July 2017

- January 2017

- December 2016

Waves Group Supports Irish Sea Contractors in Subsea Habitat Hydrodynamic Tests

April 20, 2020

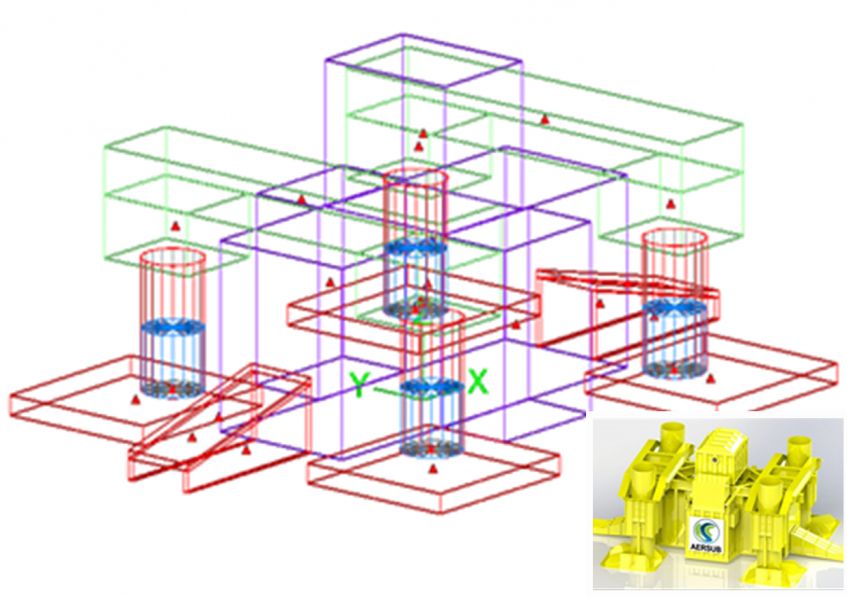

Waves Group Orcaflex Subsea Habitat model (inset) AERSUB – Irish Sea Contractors model

Waves Group are pleased to have been appointed by Irish Sea Contractors (ISC) to provide expert engineering analyses in the pre-development, installation and simulation for their Subsea power cable repair habitat design, known as Aersub. The main aims of the analyses were to define the operational envelope for deployment and its in-situ position on the sea-bed. In particular, our team defined the load and operational seastates for deployment from a typical support vessel and determined the operating conditions the body can endure on the seabed, together with recommended ballasting requirements to ensure stability.

The design, by ISC has now been developed further, manufactured and launched as the cable repair habitat called Aersub, that ISC predicts could reduce the cost of repairing offshore wind power cable by 50%. Aersub is specifically designed to enable the repair of faulty power cables in-situ subsea on the seabed and provides an alternative to more common lift-to-repair solutions. It has already been deployed successfully on a demonstration cable repair at Rosslare Europort.

Waves Group’s engineering team modelled and analysed the design using state-of the-art software, capable of dealing with complex time-domain dynamic analyses and utilising industry guidelines. Our engineers modelled the vessel (offshore crane vessel) and the subsea habitat response to the applied environmental conditions considering the dimensional and hydrodynamic properties of the subsea habitat and the vessel in order to predict the on-bottom stability and the deployment performance of the Aersub.

The on-bottom environmental loads were used as an input for a geotechnical assessment of the mudmats and the required ballast to maintain the habitat on the seabed after deployment and during abandonment following a storm event. The on-bottom stability analysis showed that the ballast requirements for the habitat were highly dependent on the installation water depth – as the waterdepth increased, the effect of waves on the habitat reduced until it was only governed by the current loads.

Our deployment analyses indicated the most likely range of significant wave height and period range that deployment and abandonment could be achieved in safely. The study used standard vessel properties and crane properties (pictured below) and advised the most beneficial orientation of the vessel to limit the critical motions of the habitat.

(L-R) Mudmat slamming loads stages and Typical vessel rigging and deck arrangement – Waves

The analyses can be applied to any marine operation and environment to allow designers to predict loads and performance and ultimately increase safety confidence and reduce costs in design and manufacture.

We are delighted to have been involved in the development of new technology that has the potential to reduce repair costs for subs-sea cables. Sub-sea cable repairs claims can be very large and disruptive to energy supplies and are well known to be a major cause for project underwriters. Through this kind of analysis and our many years’ practical experience of cable installations and repairs, we see this as an exciting development.

Waves Group’s engineering team has extensive experience in hydrodynamic analysis. Our team of naval architects, structural, marine and civil engineers has a combined experience of over 100 years. We have a large range of engineering software to support large scale engineering projects such as calculating vessel motions, development of FEA models, vessel structural analysis, mooring analyses and heavy-lifts.

To learn more about our engineering capabilities please contact mail@waves-group.co.uk.