Recent News

- Waves Group Celebrate 5 Years of Operation in Singapore

- Major Milestone Achieved in the Decommissioning of the Historic Royal Sovereign Lighthouse

- Waves Group Welcomes Captain Stanislav Ivanov as Vice President of the Houston office

- Waves Group Goes Green with Green Marine’s Project Verdant – UK’s First CTV (Crew Transfer Vessel) Powered by Hydrogen

- A New Organisational Structure for Waves Group Board of Directors

Archives

- March 2024

- December 2023

- November 2023

- June 2023

- April 2023

- February 2023

- January 2023

- November 2022

- October 2022

- September 2022

- August 2022

- July 2022

- June 2022

- May 2022

- April 2022

- March 2022

- February 2022

- September 2021

- June 2021

- May 2021

- March 2021

- February 2021

- January 2021

- December 2020

- October 2020

- September 2020

- August 2020

- July 2020

- April 2020

- March 2020

- February 2020

- January 2020

- December 2019

- November 2019

- October 2019

- September 2019

- August 2019

- June 2019

- May 2019

- April 2019

- March 2019

- February 2019

- January 2019

- November 2018

- October 2018

- September 2018

- July 2018

- May 2018

- September 2017

- July 2017

- January 2017

- December 2016

A Picture Says a Thousand words…Using cost effective 3D models to improve understanding, communications and collaboration.

August 3, 2020

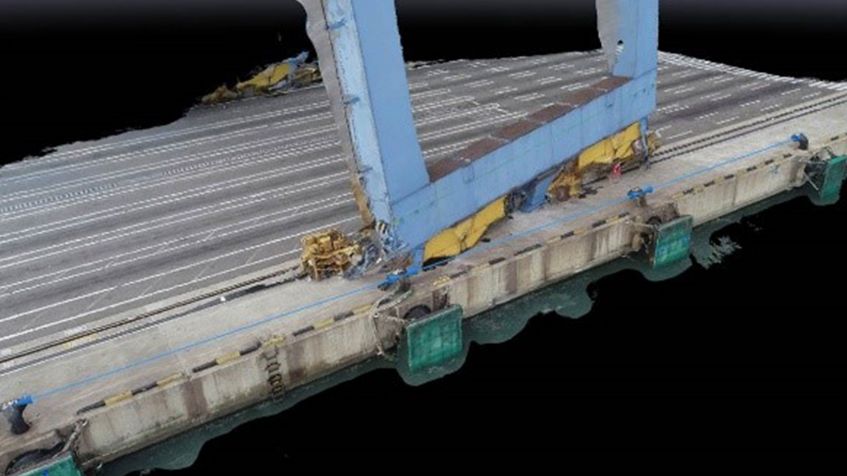

High resolution 3D model of a collapsed crane processed from drone video.

Our world is three-dimensional and most people think visually (i.e. in 3-D). However, the main method of communication in our industry is still primarily two dimensional. Even when it comes to complicated objects and situations found in casualty cases, there is still considerable reliance on written reports, 2D plans, drawings, and photos to convey and communicate often complex information.

However, technology is now allowing us to gather three-dimensional data cost effectively and quickly, allowing us to much more effectively bridge the gap between the real-world situation and our understanding of it. Making use of 3-D information can readily improve understanding of the situation and provide a better method of communication and collaboration for problem solving.

Of course, 3D data itself is nothing new, however the technology for acquiring, processing and visualising the data is now far more accessible than ever before. The value of using such technology and the visual models possible from them is translated into increased situational awareness, improved decision making and enhanced communication and collaboration – even to the extent where we are able to observe and discuss issues together within virtual reality – wherever we actually are in the world geographically.

This, coupled with the challenges thrown up by the COVID-19 pandemic in terms of restricted travel for example, mean that now more than ever, the adoption of 3D visualisations is becoming essential to allow better understanding and analysis of situations, even remotely.

One such example of technology being adopted more routinely is photogrammetry. This is the practice of creating measurable 3D models of objects in the real-world using imagery collected from cameras – and in the examples below, even basic mobile phone video is being used. For this, simple instructions were issued for video footage of damaged quaysides to be acquired locally by a non-specialist using a smart phone, which along with some basic ‘on the ground’ measurements, were used to create 3D measurable models for more detailed assessment by our experts who were unable to actually attend in person. Whilst we would always want to have an expert attend where possible, the creation of measurable 3D models by the use of non-specialists using something as simple as mobile phone video can be extremely useful in gaining insights not possible otherwise and allows us to provide our expert advice whilst the local personnel are actually at the site.

3D measurable models created from mobile phone footage.

The same process can be utilised using drone video. in the second images below drone footage was acquired of crane damage in a recent case and processed to create a 3D model from which far more information could be derived. Similarly, a drone was flown around a grounded fishing vessel and a 3D measurable model created from the video footage.

3D measurable models processed from drone video.

So why not just look at the video footage itself? Unlike the video, creating the 3D model allows us to take measurements, such as distances and cross sections, and for instance, to accurately calculate the list angle, something not possible from just looking at the video on its own. Within a 3D spatial environment, we were also able to overlay GA Plans to scale (seen in yellow) to further enhance our situational awareness in this case.

The combination of key data and the visual model allows the viewer to fully understand the condition of the asset and the situation, whilst inspecting the object from any angle.

Of course, visual models are also invaluable when no-one can see the problem at all, may be it is fully submerged! In this case, high-resolution surveys are essential to understanding the problem and then deciding on the necessary response. An excellent example of this is the survey we conducted for the UK MOD recently of the sunken wreck of the World War II tanker, the RFA WAR MEHTAR, to assess the risk of oil pollution. Here, due to the water depth and strong currents, dive surveys would have been of limited benefit and we were able to create a very highly detailed model of the vessel, overlaid with her plans to assess the risk of oil release from any residual amounts still trapped in the wreck. Using advanced hydrocarbon sensing techniques located using the 3D model, it was determined that there were no significant quantities of oil remaining onboard and so concluded that intervention was not required.

The survey, 3D model and subsequent hydrocarbon testing was instrumental in giving our client a high degree of certainty.

Our data acquisition and survey techniques have in the past year assisted salvors, insurers, shipowners and other industry stakeholders with practical solutions for risk management on major salvage and wreck removal projects as well as offshore engineering projects including subsea cable damage assessment and repair. The high-resolution imagery that is produced is also ideal for the assessment of the condition of marine assets such as port facilities and sub-sea assets to determine the condition and extent of any damage without the need for divers and using portable equipment.

3D high-resolution survey of a wreck on the seabed.

3D data plays a pivotal role in managing risks by improving the quality of the information available to responders and decision makers, therefore enabling operations to proceed with increased certainty and predictability.

For more information on our data and high-resolution survey capabilities, please contact mail@waves-group.co.uk.